HistoryCorporate Information

1966 to 1979 Founding of

DAI-ICHI CUTTER KOGYO K.K.

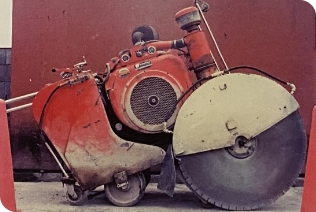

DAI-ICHI CUTTER KOGYO founded

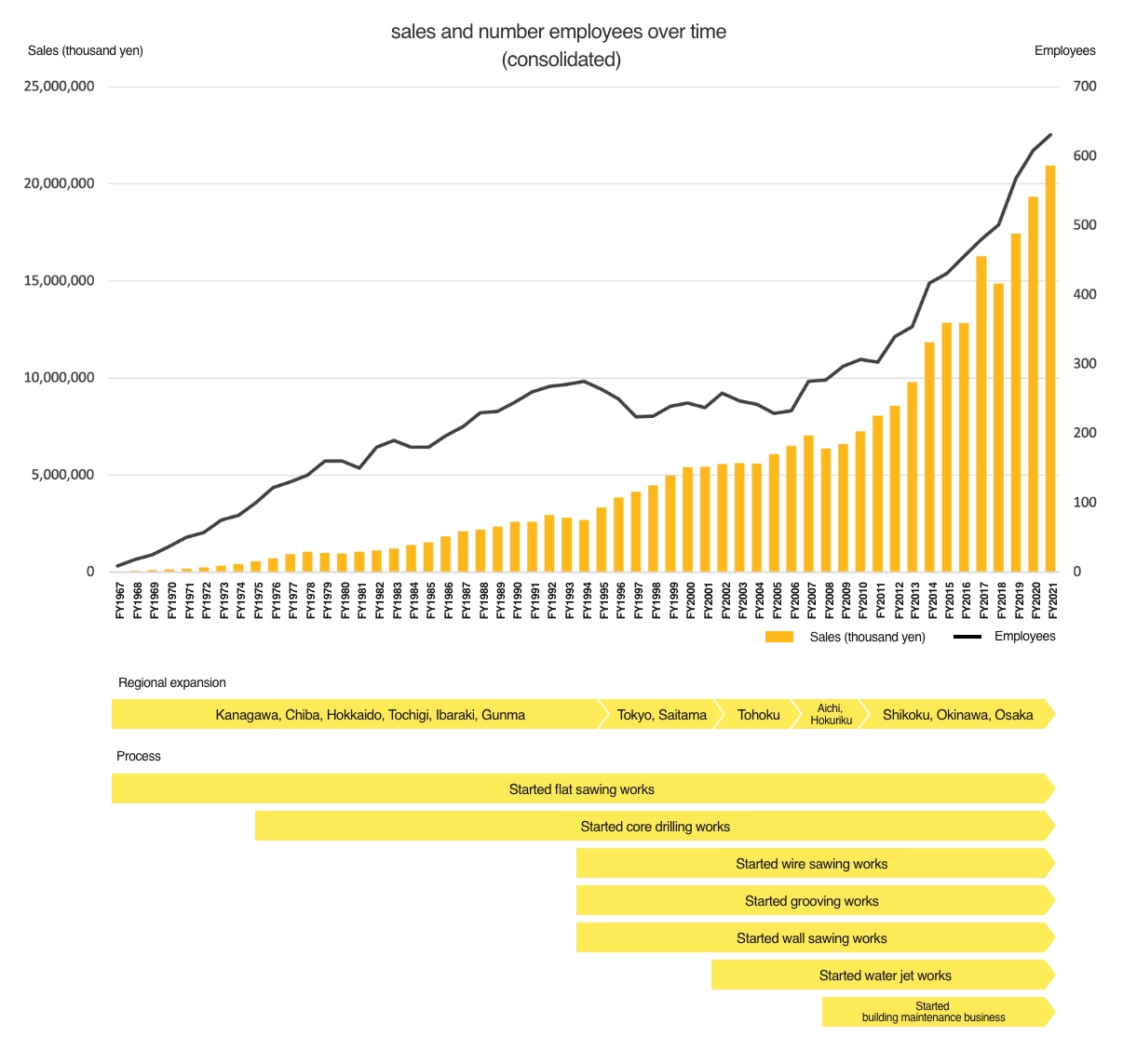

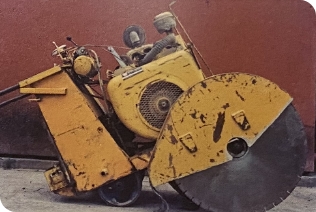

A start with three schoolmates carving out a dream for the futureMarch 1966 DAI-ICHI CUTTER KOGYO was founded by individuals to specialize in flat sawing.

August 1967 DAI-ICHI CUTTER KOGYO K.K. was established at 1588 Yanagishima, Chigasaki City, Kanagawa Prefecture with 3 million yen in capital.

1980 to 1993

Expansion of business

Construction of a series of large-scale projects

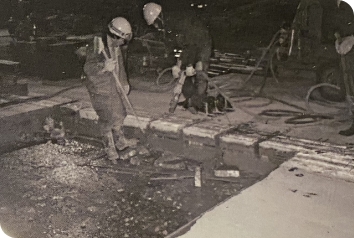

Opportunity for dramatic growth in technology and experienceSeptember 1986 Yokota Air Base runway renovation work performed.

April 1987 Chitose Airport runway renovation work performed.

We successfully completed two unprecedented large-scale projects: the complete concrete replacement of a 4,000 m long base runway (1986) and installation of buried light fixtures on an airport runway (1987).This experience served as a stepping stone for DAI-ICHI CUTTER KOGYO for future business expansion.

1994 to 2004

Expansion of business areas, listing of shares

Entry into new technologies and expansion of construction areas

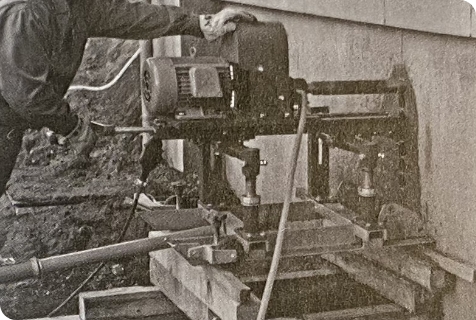

Technical improvements made and partnerships with other companies formed through challenging construction projects.July 1995 Started wire sawing and grooving works.

August 1995 Started wall sawing works.

Water jet business

Birth of a second business pillar that can handle “cutting,” “chipping,” “washing,” “peeling,” and “scraping”July 2002 Started water jet works.

Preparations were underway from around 2022 to establish a new water jet installation unit.

Initially, most of the construction was done as work to prevent highway spalling, but after the Niigata Chuetsu Earthquake in 2004, we began repair work on railroad viaducts and entered the field of concrete chipping work around reinforcing bars.

Prior to the move to a new building in 2005, the Water Jet Division was spun off as an independent organization.

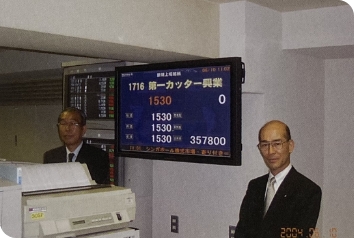

Listing of shares

Listing of the first construction company specializing in cutting, one of our goals since inceptionJune 2004 Listed on JASDAQ (Securities code: 1716).

More than 30 years had passed since the company was founded, and a strong financial structure had been built. However, we decided to go public based on a belief that more stakeholders watching over us would ensure even more stable management.

Since there was no precedent for a construction company specializing in cutting to be listed, it was initially difficult to get securities companies to understand the business. However, we successfully listed on JASDAQ on June 10, 2004.

From 2005

Expansion overseas and entry to new fields

Participation in projects overseas

Becoming a company protecting social infrastructure worldwideFebruary 2005 First overseas work performed in Indonesia.

Bursting work was performed in Indonesia in 2005 as part of ODA (Official Development Assistance).

The project was to remove scoured bridge piers in a short time. However, we had to wait for six days at the site because the cargo was delayed due to the severely-disrupted customs clearance at that time. As a result, only the last section of the piers was done using bursters.

This would be the Company’s first project outside of Japan.

Since then, wall saw work was done in Nigeria in 2012, special core drilling work was done in Vietnam in 2016, and since 2017, large scale works in Kuwait have been performed in collaboration with Group companies with locally-produced machinery.

Establishment of a system at the new location

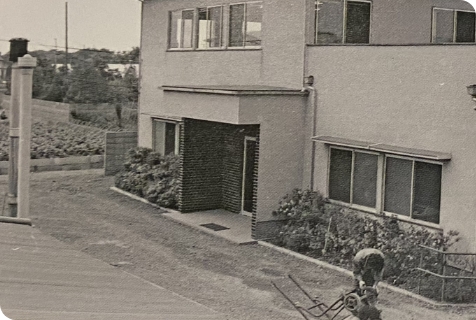

Consideration for noise issues in residential areasAugust 2005 Head office relocated to 833 Hagisono, Chigasaki City, Kanagawa Prefecture.

The Company purchased the land and buildings of the former Matsushita Denso Co. Ltd., which housed a three story factory building and a five-story office building, and relocated to the current location (833 Hagisono, Chigasaki City), a dedicated factory district.

With the following purchase of the adjacent land and buildings in 2010, the current site area is approximately 16,500 square meters.

A parking lot and machine/materials storage area, which had previously been rented outside the property, were now established on the site.

Today, the site of the former head office at Yanagishima is a quiet residential area.

Building maintenance business

The birth of a third business pillar backed by the strength of careful work and high-quality equipmentJuly 2009 Started building maintenance business.

When the water jet business started to take off, the search started for a third pillar to follow the diamond method and water jet method.

In April 2009, the Building Maintenance Division was established after studying drain pipe cleaning that receives orders regularly from cutting work sites.

Entry into surface treatment field

Commercialization of the shot blasting method after repeated studiesDecember 2010 Constructions using shot blasting started.

Shot blasting was also used in decontamination work following the accident at TEPCO’s Fukushima Daiichi Nuclear Power Plant in March 2011.

Initially, high-pressure water washing was the primary method of decontamination. However, the cutting power of blasting was highly valued, as washing requires more wastewater treatment.

Promotion of Mergers & Acquisitions

For further expansion of technology and servicesJuly 2019 ASIRE Corporation of Kanagawa Prefecture became a subsidiary.

April 2020 UNIPEC Co.,Ltd. of Hyogo Prefecture became a subsidiary.

Since going public, we have actively engaged in M&A to diversify our construction methods.

Most recently, ASIRE, a long-established company with high technological capabilities in the water jet method, became a subsidiary, followed the next year's acquisition of UNIPEC, a company engaged in cleaning work for plant facilities.

This strengthens the core business of DAI-ICHI CUTTER’s core business, which consists of “cutting,” “chipping,” “washing,” “peeling,” and “scraping.”

Sales office renewal

Pursuit a comfortable working environmentDecember 2020 Sendai Office relocated.

May 2021 Tochigi Office relocated.

August 2021 Takasaki Office relocated.

June 2022 Mito Office relocated.

Since 2020, we are relocating and rebuilding our sales offices to serve as a foundation for further company growth against a backdrop of increased productivity and expansion of the intermediate treatment business.

We will continue to grow to become a company

that will be called first (dai-ichi) in the world and in the universe

to protect the safety and security of society.